Project: Logic modular manufacture and install

Mitanium Washrooms were tasked to build and install a luxury modular Logic washroom solution for a client that runs a luxury wedding venue for upto 1000 guests per event near Heathrow. The system was connected to the mains but not to a "local" mains connection. The connection was 200m from the location of the toilets and had to be pumped. Mitanium Washrooms built and installed the Logic toilet system and then installed pumping stations to carry the waste to the access point.

Manufacture and Install

The Logic range of units is built by us at our workshop from the ground up. Starting off with the vanity, cubicle and urinal frames, we then clad the frame work with oak and finish with geo panels the customers spec. Oak doors with top spec handles, locks and toilet roll holders are installed, with the ceramic goods installed last. All the finishes, fixtures and fittings are fully customisable to the clients spec.

Once the units are completed they are wrapped and loaded onto vehicles to be taken to site. The install on a system this size takes on average a day to complete including all the water and waste connections. The system can be directly plumbed into the mains, but in this case, pumping stations were added to carry the effluent 200m to the nearest access point.

Flooring fitted

Geo panel installed

Cubicles with sinks

Completion of female side

Completion of male side

Flooring fitted

Oak Installation

Install of male side

Vanity units

Install of female side

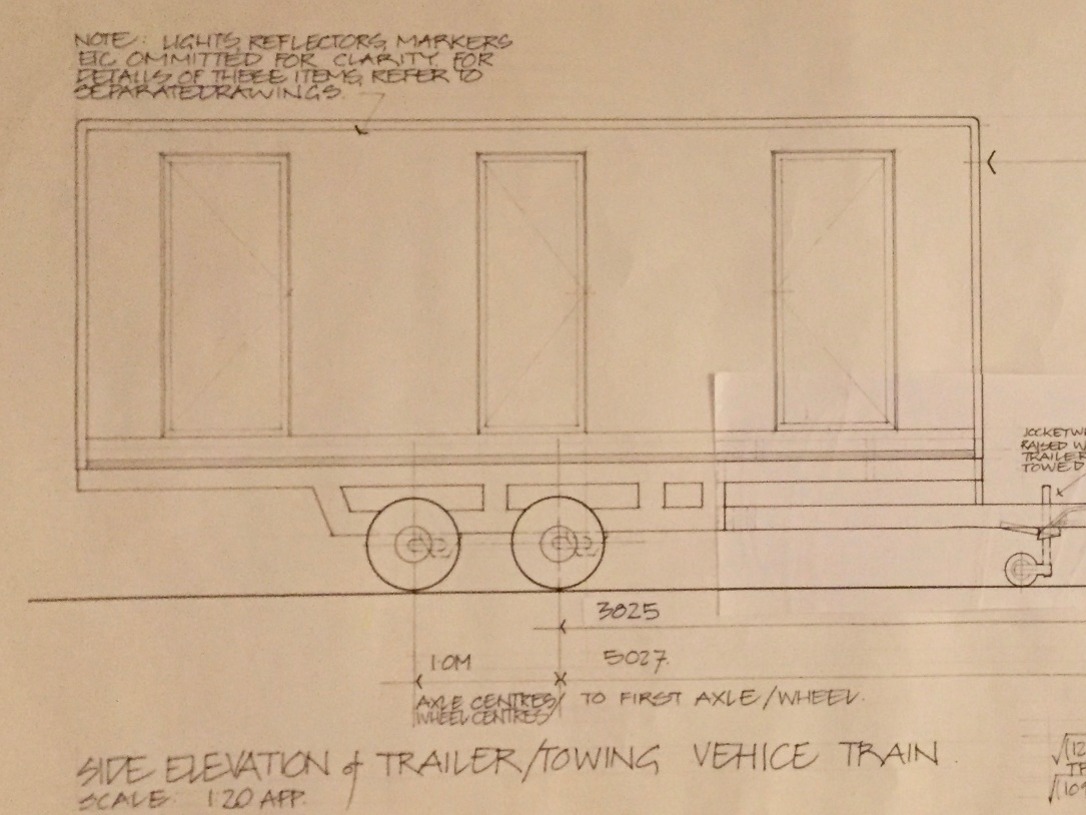

Project: The uber trailer

Mitanium Washrooms were tasked with building an "uber" or oversized special build trailer for a luxury wedding venue in Brighton. The trailer was to be mains connected in its initial form, with the option to have it swiftly converted to recycle once it had finished its stint at the venue.

Moving forwards

Mitanium Washrooms were tasked with building an "uber" or oversized special build trailer for a luxury wedding venue in Brighton. The trailer was to be mains connected in its initial form, with the option to have it swiftly converted to recycle once it had finished its stint at the venue.

Clients Spec

Because this was to be a mainly site located unit, the client requested it be built to the full width that is allowed on UK roads. This gave the interior of the unit a much more spacious feel, although feeling a little wide on the way down to Brighton on the narrow roads of the Kent countryside.

The exterior of the unit was finished with oak sided steps with stainless steel hand rails. The box and floor of the unit contained zero timber insuring a guaranteed long life. Made from Eco font foam filled panels and a specially made foam engineered floor the unit was both strong and light. Internally fitted out in oak with glass bowl sinks and top end bathroom fittings, the unit was really finished to impress.

Exterior Finished Product

Chassis Completion

Boxing Production

Chassis Fabrication

Plans for the Uber Trailer

Chassis Galv and fit up

Mobile trailer in production

Interior Finished Product